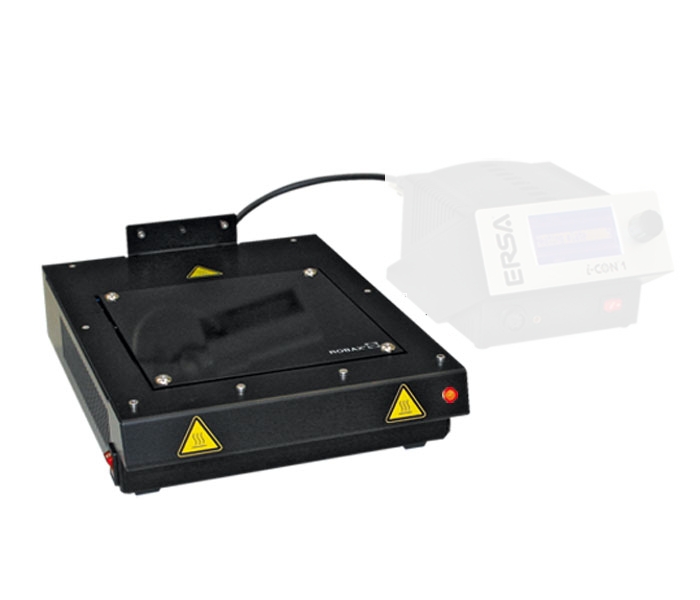

ERSA Heating Plate 800W

The infrared heating plate 0IRHP100A enables the underside preheating of PCBs during manual soldering and desoldering and in rework. The safe and powerful infrared heating technology offers enormous advantages.

The operating temperature of the soldering iron, the internally heated SMD tweezers or the desoldering iron can be significantly reduced. Lower tip temperatures reduce the risk of damage to the circuit board, while at the same time significantly extending the tip life.

To control the heating plate, use a soldering station of the type i-CON1 C or i-CON2 C, taking care to use the necessary interface connection!

The control cable can be found under item number: 0IRHP100A-14

This means that no further control unit is required for the heating plate at the workstation and you can then use the soldering station to operate other soldering tools, such as:

the i-TOOL soldering iron (150 W),

the CHIP TOOL internally heated SMD desoldering tweezers (2 x 30 W) or

the X-TOOL (120 W) for desoldering conventional components.

Depending on the application and size of the printed circuit board, Ersa also offers three different options for handling PCBs. The large digital display and the user-friendly, menu-driven control of the i-CON C offer maximum process control in 10 languages.

Features:

Contactless preheating of assemblies during lead-free hand soldering

Preheating of SMD components

Heating surface 125 x 125 mm

Reflow soldering of single-sided printed circuit boards

Drying of pastes and adhesives

Adjustable heating plate in six stages

Applications:

Preheating of SMD components and assemblies

Curing and drying of pastes, varnishes, adhesives, etc.

Reflow soldering of single-sided printed circuit boards

Preheating of BGA components to avoid the “popcorning effect”

Uniform BGA heating for ‘reballing’ applications